Specialised Equipment

Specialised Equipment

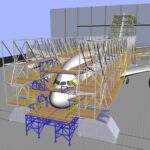

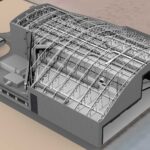

AIRCRAFT HANGAR MAINTENANCE EQUIPMENT

Aircraft Support Industries provides up to full turnkey design and construct solutions for aircraft hangar maintenance facilities. As part of this service to clients, we can design and/or source specialist aircraft maintenance and ground support equipment such as:

- Overhead Roof Mounted Cranes

- Teleplatforms

- Docking Systems

- Retraction Wheel Pits

In many cases the support and configuration of this equipment directly impinges on the main hangar design. The seamless integration of the hangar structure and facilities into a total solution is arguably one of the most significant benefits Aircraft Support Industries can bring to a project and also one of the areas where Aircraft Support Industries can demonstrate significant cost savings when allowed to ‘value engineer’ the tender design for a proposed new facility.

OVERHEAD ROOF MOUNTED CRANES

Cranes are the workhorses of a heavy maintenance hangar facility, providing the ability to both lift full engines and also the numerous light equipment lifts necessary. 10T or 15T SWL cranes are typical. The hangar roof must be specially designed for strength and stiffness to allow proper operation of roof mounted cranes.

TELEPLATFORMS

Teleplatforms comprise a vertically telescoping mast supported at roof level by a gantry running on rails in the roof. At the bottom end of the mast is a work platform that can be raised, lowered and rotated, providing the ideal mechanism for spot maintenance on the aircraft body. Teleplatforms are often used for maintenance on the tail fins of aircraft. Teleplatform dead weight is substantial and the hangar roof must be specially designed.

HORIZONTAL SLIDING DOORS

Horizontal sliding doors designed by ASI run on flanged wheels at the bottom and are guided at the top by special vertical roller assemblies which importantly allow for the hangar front wall movements, to ensure the doors perform well in all circumstances. These doors are commonly specified by clients. Aircraft Support Industries hangar doors are invariably cost effective compared to doors supplied by 3rd party manufacturers.

VERTICAL LIFT DOORS

Vertical lift doors operate much like a roller door except they comprise a light structural framework supporting one or more layers of fabric like material. They are an elegant solution, in particular where either aesthetics or space limitations dictate that conventional sliding doors are inappropriate. Special consideration needs to be given to the performance of the front support of the hangar to meet the door functional requirements.

RETRACTION WHEEL PITS

In ground undercarriage pits are designed to be incorporated into the hangar concrete floors. Constructed to allow aircraft to roll over a platform, which can be lowered once the aircraft is correctly positioned, the pits allow servicing of the landing gear without the need to fully jack. The pits are provided with service points for compressed air, power and lighting as required.

SERVICE PITS

A range of service pits that are cast insitu providing air, water, electricity at strategic locations throughout the hangar can be incorporated into the initial design.A range of service pits that are cast insitu providing air, water, electricity at strategic locations throughout the hangar can be incorporated into the initial design.

PAINT BOOTHS

Whether for low production batch process, or high production conveyor system, a state-of-the-art booth can be designed and built to fit the clients operation. Booths are currently used for a vast range of products that include electronic components and printed circuit boards, business jet aircraft, helicopters, aerospace sub-assembly parts, landing gear, military ordinance and general aviation aircraft. Each paint booth system is designed with the clients particular air flow, filtration, temperature, humidity, and lighting needs in mind.